Slabs

Shoolagiri Factory

Crafted Precision: Our Granite Slab Manufacturing Process Explained

Our Materials

Shoolagiri

Welcome to our granite factory nestled in the heart of Shoolagiri, located in the Krishnagiri district of Tamil Nadu, India, is renowned for its scenic beauty, vibrant culture and flourishing industries. Here, innovation meets tradition. Equipped with cutting-edge technology, our facility boasts 2 high-tech monowire saw machines and a formidable Italian Gantry crane weighing 70 tonnes by Faedo. With 6 OT cranes weighing 10 tonnes each, precision is our hallmark. Our arsenal includes 4 Breton Multiwire saws with 76 wires, 3 Gangsaws by Basanti, a Breton Polishing machine with 22 heads, and a Keda grinding machine with 14 heads. Plus, our Breton resin line with 43 trays ensures impeccable finishing. With our EOT (Electric Overhead Traveling) Crane overseeing operations, excellence is our constant companion.

Why Choose Us

Wanna know what people think about us? Check out our Review

Choose Aryan Granites for exquisite slabs and timeless monuments that make memories and keep them alive eternally.

With our visionary craftsmanship, we blend emotional resonance with unparalleled quality,

We ensure that each piece reflects enduring love and surpasses expectations globally.

Aryan Granites makes sure that any request of customisation is met that pleases our clientele.

Choose us for our flawless customer service, and a product that fulfils all your requirements.

Slabs

- Granite slab manufacturing begins with block arrival via bulk transport from quarries.

- Robust gantry cranes expertly unload blocks, handling up to 70 tonnes.

- Skilled artisans use precision monowire saws for meticulous dressing.

- Advanced multiwire saws ensure consistent quality and dimension during development.

- State-of-the-art Keda grinding machines refine each slab for a perfect finish.

- Slabs undergo treatment in our Breton Resin machine for durability and beauty.

- Meticulous polishing enhances the final appearance.

- Finished slabs are carefully crated and dispatched.

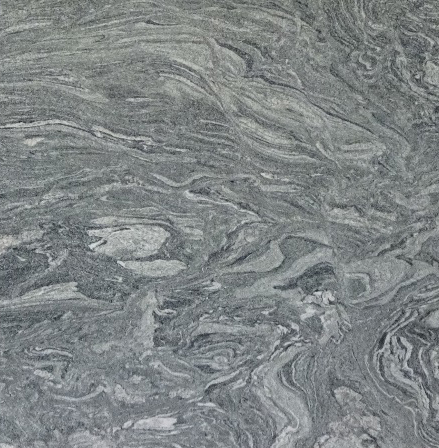

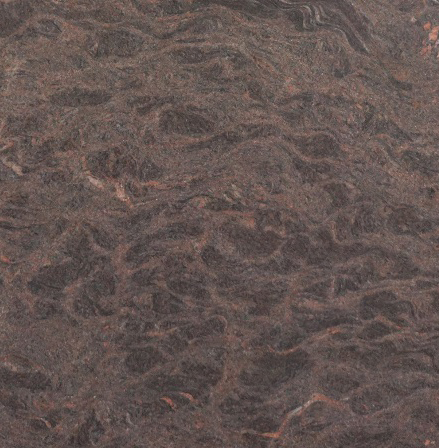

Types of Stones

Several types of stones are used to create slabs and monuments. Marble is a popular choice for countertops, flooring, and decorative accents. Slate has a natural cleft surface and earthy tones, slate is often used for outdoor projects like patio flooring and wall cladding. Limestone offers a soft, muted appearance and subtle variations in colour, limestone is frequently utilised in architectural and decorative elements.

Process

At our granite slab manufacturing company, our process begins with the arrival of blocks via bulk transport from quarries and mines. These blocks are expertly unloaded using our robust gantry cranes, capable of handling up to 70 tonnes of weight. Next, our skilled artisans employ precision monowire saws for meticulous dressing, tailored to meet the specific preferences of our discerning clients. Subsequently, the slabs undergo development with our advanced multiwire saws, ensuring consistent quality and dimension. For the perfect finish, our state-of-the-art Keda grinding machines refine each slab to perfection. To enhance durability and beauty, the slabs undergo treatment in our Breton Resin machine, followed by meticulous polishing. Finally, after careful crating, the finished slabs are dispatched

How We Work

Excellence in Granite Slabs

Here is the step-by-step process of monument production at Aryan Granites:

Procurement

We source premium quality granite directly from quarries worldwide with our Italian Gantry crane, ensuring the selection of only the finest raw materials for our slabs.

Treatment

High tech monowire machines are among our state-of-the-art machinery. Combined with skilled craftsmanship, we transform raw granite into exquisite slabs, meticulously treating each piece to enhance its natural beauty and durability.

Polishing

With our world class Breton Polishing machine, we achieve a flawless finish on every slab, accentuating the granite's innate patterns and colours and exceeding the expectations of our discerning clientele.

Export

Committed to excellence in every aspect of our business, we export our superior quality granite slabs to clients globally, delivering unmatched beauty, durability, and satisfaction.